The store will not work correctly in the case when cookies are disabled.

- Home

- lightWELD Laser Welding [Why Choose Lightweld?]

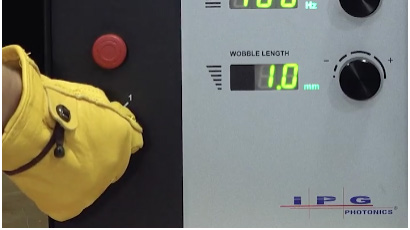

LightWELD - Factory Presets Ensure Optimized Welds & Cleaning

- Simple preset selection ensures consistent high-quality laser welds and cleaning

- Presets include wobble welding function to accommodate wider seams and for parts with poor fit-up

- Operators can instantly switch between presets to process multiple material-thickness combinations

- Advanced operators can customize presets, save for future use and can lightWELD be used by novice operators to produce the same results

- Novice operators require less training which reduces labor costs while preserving quality, increasing productivity and decreasing scrap

LightWELD is Versitle and Safe

- Ergonomic, compact and proven to be the most comfortable and easy to use laser gun with built-in wobble welding functionality.

- 2-step trigger and part contact sensor enhance operator safety

- Purpose-built nozzle tips for various weld joint types and pre and post weld cleaning applications

- Quickly switch from standard laser welding to wire welding, and from laser welding to laser cleaning

- A single cable from the unit delivers laser power, gas and control connections to the gun

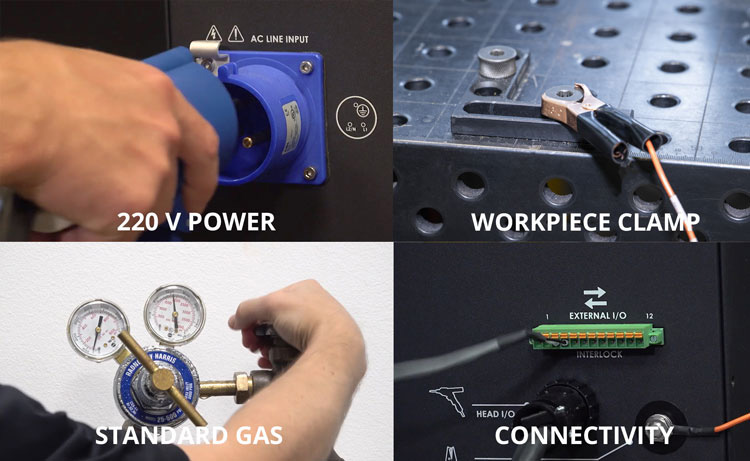

Fast and Easy Setup

- Clearly labeled rear connections make getting started fast and easy

- Simply plug in power cord and gas connection, attach clamp to work surface, and the system is ready to go.

- Laser power, gas, and gun control are delivered through a single cable.

- An ethernet computer connection provides access to advanced parameter settings to fine tune and save process parameters.

LightWELD Operator Safety Features

- Key switch control to secure system from unauthorized operation

- Emergency-stop button for immediate shut down

- Safety interlock verifies integrity of laser delivery to the welding gun

- 2-step weld gun trigger, enable and then fire, for intentional operation

- Part contact electrical interlock turns off the laser power if the welding head is not in contact with the welded parts

- Door switch interlock circuits shut down laser if anyone other than operator unexpectedly enters the welding area

Learn More - Download LightWeld Brouchure

Learn More - Download LightWeld Brouchure