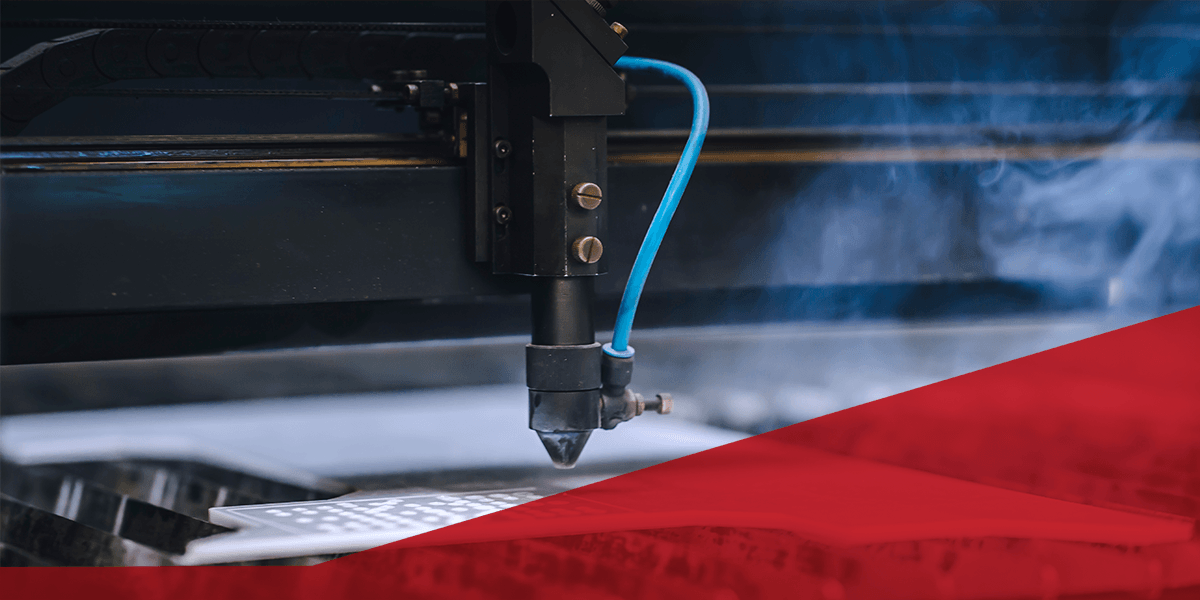

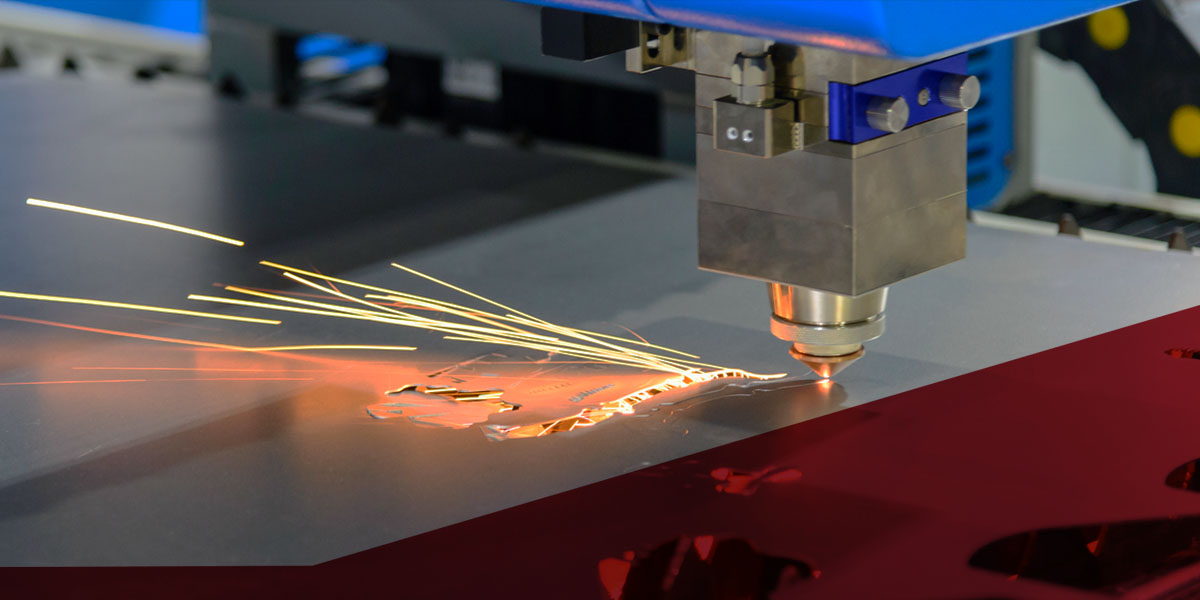

Laser cutting safety is essential for compliance, employee protection and equipment longevity. Following safety regulations helps prevent accidents, injuries, fire hazards and machine damage, making it a critical part of laser cutting management.

To maintain a safe environment, you must enforce safe operation rules and ensure employees wear the proper personal protective equipment (PPE). You should also provide safety signage, train employees, establish fire safety protocols, follow ventilation requirements and maintain equipment.

Importance of Laser Cutter Safety

Laser cutting safety is important because it offers the following advantages:

Operator Health and Safety

Laser cutter safety protects your employees from potential fiber laser cutting machine accidents. Enforcing safety guidelines and protocols to prevent or minimize injuries and health complications gives your staff peace of mind. This can also increase workplace morale and employee retention because workers are more likely to stay with a company they trust and feel safe with.

Compliance

Following safety guidelines helps you comply with government and industry regulations. Operating machines safely can help you avoid fines and penalties for improper usage.

Machine Longevity

Practicing safe machine operation can also help your equipment last longer. Observing guidelines for proper cutting machine operation and maintenance can help prevent damage, increase machine uptime and extend equipment longevity, saving you money on repairs and replacements.

Common Laser Cutting Hazards

Laser cutting equipment operation requires safety precautions because it can cause the following types of hazards:

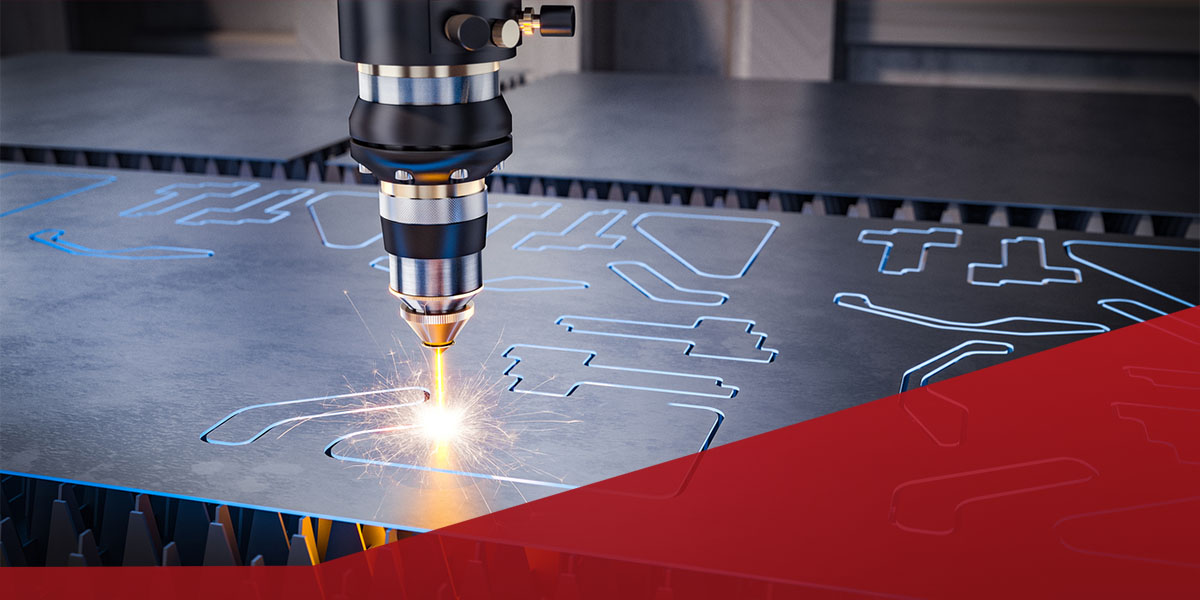

Fire

Laser cutting involves burning substrate material away, which generates high heat. Materials, dirt and debris can catch fire, so it's vital to minimize fire hazards, keep fire safety equipment on hand and establish a fire evacuation plan.

Hazardous Fumes and Vapors

Operators can potentially inhale laser-cutting byproducts, so protecting the face and lungs during operation is crucial. Cutting certain materials can release laser-generated air contaminants (LGACs), such as the following:

- Toluene

- Benzene

- Isocyanates

- Hydrochloric acid

Potential Eye and Skin Damage

A laser is powerful enough to cause eye damage or burn the skin if an employee looks directly at a beam or contacts it. Employees must wear the proper safety equipment to protect themselves from injuries.

How to Use a Laser Cutter Safely

You and your staff can use a laser cutter safely with the following rules and best practices:

Practice Safe Operation and Maintenance

Each employee should keep the following operational guidelines in mind when operating or maintaining laser cutting equipment:

- Never leave systems unattended during operation.

- Maintain a clean space free of clutter, debris and flammable materials around laser cutting machines.

- Clean the laser cutter's interior spaces.

- Inspect equipment between uses.

- Ensure interlocks work properly and covers are in place before operating the laser.

- Avoid modifying or disabling the laser system's safety features.

- Ensure the viewport is in good condition before operation.

- Replace or repair the viewport if you notice damage, missing doors or defective safety interlocks.

- Never defeat safety laser interlocks the manufacturer built into the cutting machine because this can enable the beam to escape the cutter.

- Turn lasers off and use beam caps or shutters when you don't require laser transmission.

Limit Cutting to the Appropriate Materials

Manufacturers design laser cutting machines to cut specific materials safely. Check your machine's user manual for its intended materials, and limit your cutting operations to only those materials. Working with compatible materials prevents your laser cutting machine from producing corrosive or toxic fumes.

Use Personal Protective Equipment

PPE is crucial for workers operating laser cutting machines. Ensure each operator wears the following PPE during operation and equipment maintenance:

- Safety glasses: Operators must avoid looking directly into a laser beam and wear safety glasses to protect their eyes from particles and laser radiation during use. Ensure each set of safety glasses is rated for the specific laser's optical density (OD).

- Protective clothing: Clothing such as aprons and lab coats help protect the skin from potential burns. Employees should avoid wearing loose clothing and accessories such as jewelry to prevent them from getting caught in a machine's moving parts.

- Gloves: Flame-retardant, heat-resistant gloves protect employees' hands from chemical exposure, burns and electric shock.

Follow Laser Cutter Ventilation Requirements

To properly ventilate a laser cutter machine, you must exhaust it via ductwork approved by the Division of Facilities Planning and Management (FP&M). An FP&M-approved exhaust system enables your machine's emissions to exit the facility effectively. To comply with regulations and maintain reliable ventilation, you must install the system properly and ensure it meets the manufacturer's specifications with the following features:

- Adequate airflow: Adequate airflow is necessary to move the amount of fumes your equipment emits. Check your laser cutter machine's manual for the required airflow.

- Sufficient pressure: Similar to airflow, your ventilation system needs the appropriate pressure to move contaminants from your equipment space to outside your facility.

- Quality filtration: Ventilation systems require quality filtration to capture airborne gases, odors and particles.

- Strong ductwork: Your ventilation system's ductwork must be strong enough to handle vacuum pressure.

Use the Proper Safety Signage

Safety signs inform and remind workers about laser cutter hazards, helping them maintain safe habits during equipment operation and maintenance. Contact your state's Environmental Health and Safety (EH&S) Radiation Safety Office to obtain the proper signs for your facility.

Train Operators

Before operators work with laser cutting equipment, you must provide thorough training on the following topics:

- Operating procedures

- Potential hazards

- Safety precautions

Establish Fire Safety Protocols

Your facility should contain industrial safety supplies such as CO2 fire extinguishers and fire blankets, and these supplies must be within easy reach. It's also important to develop a fire evacuation plan, ensure all personnel are aware of it and train all personnel to prevent fire hazards within the facility.

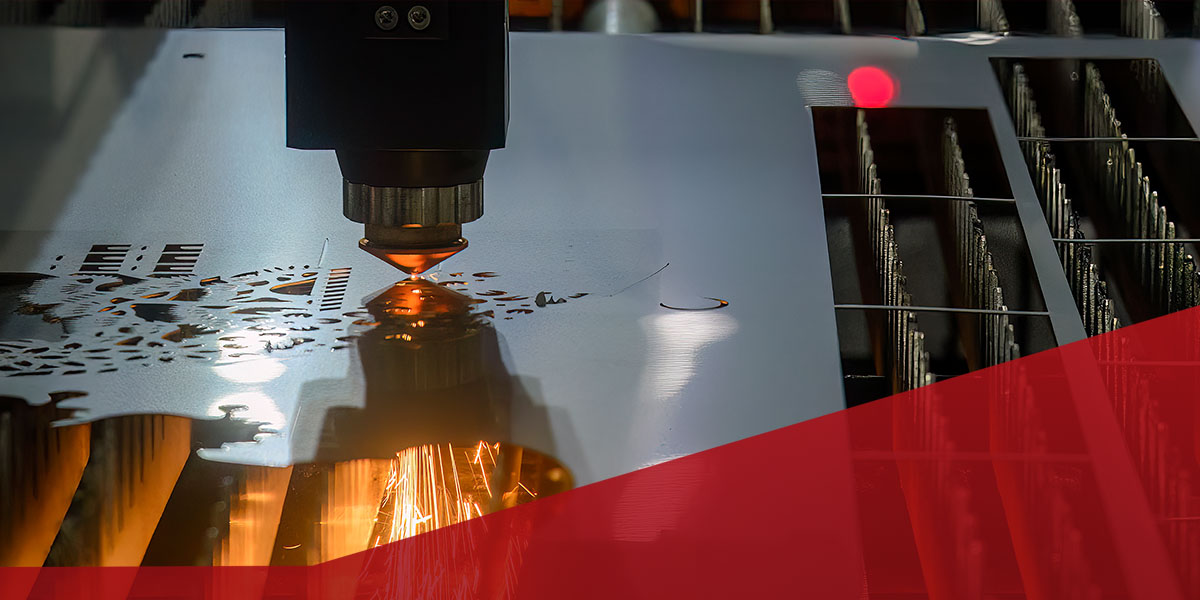

Maintain Equipment and Replace Parts as Needed

Laser cutting equipment depends on well-maintained components to operate safely. Monitor your equipment, schedule regular inspections and maintenance, and order new parts when necessary to ensure your equipment is in top shape.

Maintain Safe Operation With Quality Parts and Services From Alternative Parts, Inc.

Quality, well-maintained equipment is crucial to laser cutting safety. Alternative Parts, Inc. manufactures and carries a wide range of laser cutting parts compatible with the industry's top brands, such as Amada, Hypertherm and Cincinnati. We also offer on-site service for Amada Fabricating Equipment and Finn Power Crimping Machines.

At Alternative Parts, Inc., we are dedicated to offering quality parts, maintenance and repair at competitive prices so you can maintain safe, dependable equipment. Contact us to learn more about our available parts and services.