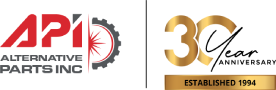

A Brief Overview of Laser Cutting Application Areas

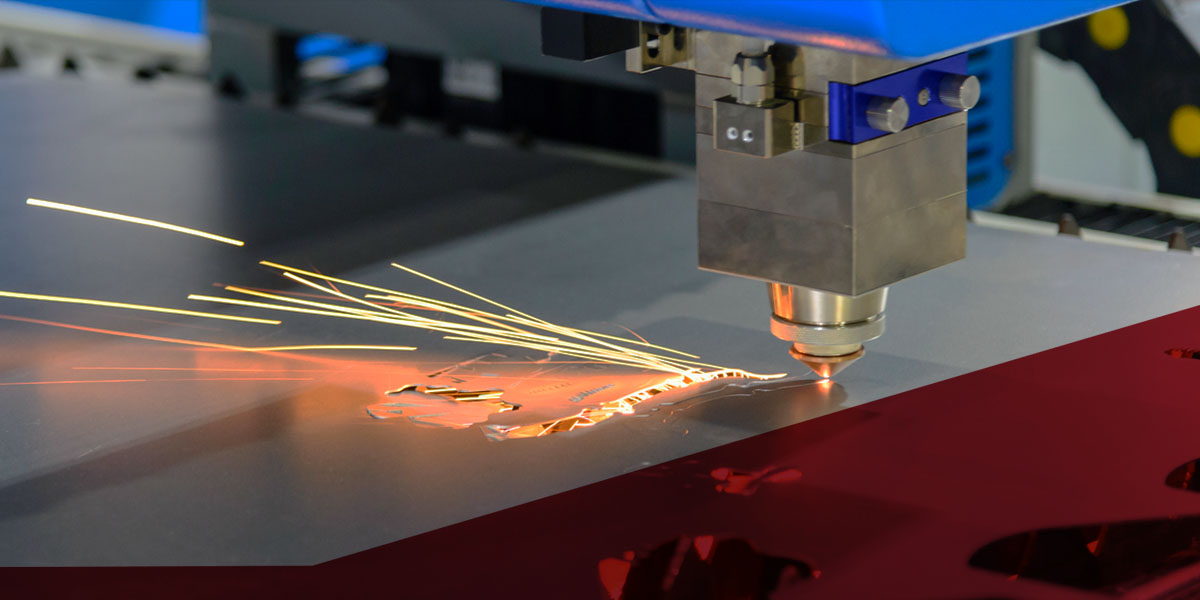

Laser cutting is one of today's most innovative manufacturing technologies with use cases across virtually every industry.

And those applications are only going to grow in the future. Experts predict significant expansion in the American industrial laser cutting machine market over the next few years due to rising demand for the machinery. Here, we'll explore some of the most common laser cutting application areas.

1. Automotive

In the past, automotive manufacturers used the stamping and die-cutting method to produce vehicle parts — but it quickly became apparent that this technique was too inefficient to keep up with rapidly rising demand.

Today's auto manufacturers use laser cutting machines to produce various internal and external vehicle components such as:

- Body panels

- Engine components

- Frame and chassis parts

- Exhaust systems

- Suspensions

- Die castings

Lightweighting is another emerging application in the industry that swaps out heavy conventional materials with lighter ones to boost the vehicle's fuel efficiency, reduce manufacturing costs and improve overall sustainability.

2. Electronics and Electrical Engineering

From pocket-sized phones to ultra-thin laptops, today's consumer electronics are both smaller and more powerful than ever.

The precision and efficiency of fiber laser cutters enables technology manufacturers to quickly cut tiny yet intricate components like printed circuit boards (PCBs) while maintaining the cleanest, most accurate cuts.

Some other industry applications include:

- Engraving: Fiber laser cutters can create clean markings such as barcodes, serial numbers and regulatory labels to improve traceability and compliance. You can also use them to customize consumer products with personalized engravings for added value.

- Sustainability: Because steps like filing and grinding are unnecessary with laser cutting, you can minimize waste and streamline your manufacturing processes.

- Efficiency: Fiber laser cutters can cut electronic components in significantly less time than a conventional machine, maximizing productivity and enhancing profitability.

3. Military and Defense

The MIL-STD-130 standard, also known as “Identification Marking of U.S. Military Property,” requires manufacturers to create durable, legible equipment labels to identify items.

That's why defense and military equipment manufacturers use laser cutting technology. This technique enables you to produce reliable, high-quality pieces fit for use in even the most extreme environments, such as:

- Gear: Laser cutters enable manufacturers to add long-lasting identifying text and graphics to gear such as flashlights, firearms, knives and more.

- Vehicles: Vehicle manufacturers can use laser cutters to produce components like high-stress armor plating and rugged body panels for specialized military vehicles.

- Internal components: Military equipment must be able to withstand extreme temperatures, physical stress and other intense environmental forces, and laser cutting machines are the ideal tool for achieving these results.

4. Aerospace

Quality and precision are critical for aerospace manufacturers, as their products spend long hours exposed to extreme conditions such as below-freezing temperatures and intense atmospheric forces. Some common applications include:

- Structural components: Fiber laser cutters create precise cuts in lightweight metals like titanium and aluminum, enabling manufacturers to create high-quality body panels, aircraft fuselage components and wing structures.

- Rapid prototyping: Innovation moves rapidly in the aerospace sector, and laser cutting machines make it possible to build high-quality prototypes in less time than traditional manufacturing techniques.

- Material versatility: Using both carbon dioxide (CO2) and fiber laser cutters, companies can experiment with new and unique materials for various parts.

5. Manufacturing

Although manufacturing is a broad industry that includes various sectors, all manufacturing plants have the same basic requirements.

Some of the most notable industrial applications of laser cutting machines include:

- Medical devices: Laser cutters produce components with clean, accurate lines that meet the healthcare industry's stringent requirements. For example, you can use a laser cutter to create surgical instruments, X-ray machine components, internal devices like pacemakers and stents, and so much more.

- Heavy equipment: Equipment manufacturers for construction, warehousing and other types of heavy equipment can benefit from the tight tolerances and clean cuts of laser cutting machines.

- Metal fabrication: Fiber laser cutters can be used to cut various metals, including brass, aluminum, steel and more. These machines can also accurately cut detailed markings into metal surfaces for easier identification and traceability.

6. Textiles and Fashion

Innovation is one of the best ways for textile producers and fashion brands to stand out from their competition. Designers can use a commercial laser cutter to turn virtually any fabric into today's hottest styles.

Some examples include:

- Fabric cutting: Laser cutting is excellent for creating intricate designs in apparel, especially for high fashion and activewear companies using delicate materials.

- Customization: You can use laser cutting to efficiently create custom pieces with personalized engravings, made-to-order cutouts and more.

- Jewelry and accessories: Designers can use laser cutting machines to push the boundaries in jewelry design with greater precision and control over their patterns.

7. Construction and Architecture

Laser cutting has many potential applications in both construction and architecture, such as:

- Structural components: Many construction companies use fiber laser cutters to precisely cut steel panels, pipes, roofing panels and more.

- Architectural pieces: CO2 laser cutters can create architectural panels with intricate designs and patterns that would be near impossible using conventional methods.

- Bespoke pieces: Architects can use laser cutters to create project-specific pieces, such as staircases and custom paneling, with rapid turnaround times.

Both CO2 and fiber laser cutters are excellent tools for this industry, as many building projects tend to use various different materials. For example, companies can use fiber cutters for metal components and CO2 cutters for all others.

8. Signage and Displays

Laser cutters can create clear, visually appealing acrylic and metal signs for various business applications, including but not limited to:

- Retail storefronts

- Construction sites

- Restaurants

- Educational institutions

- Office buildings

- Religious organizations

- Public transportation stations

Whether a company needs clear and legible signage to comply with safety regulations or an attention-grabbing display to draw customers in, laser cutting machines are excellent tools for achieving these results.

9. Shipbuilding and Marine

Like in aerospace, automotive and military manufacturing, shipbuilders and other marine manufacturers need to stay within tight tolerances and regulations to operate legally.

Laser cutters are excellent for producing high-quality cuts and welds for safe and functional marine vessel components, such as:

- Body panels

- Window, hatch and door frames

- Tubes and pipes

- Support systems

- Brackets and other structural components

Laser cutting machinery is also useful for efficient maintenance and repairs. For example, you could use a fiber laser cutter to cut custom replacement parts for older vessels.

Expand Your Product Offerings With an Industrial Laser Cutting Machine

Does your company manufacture high-precision components? Having an efficient laser cutter in your facility can help you save significant time and resources regardless of the sector you serve.

At Alternative Parts, Inc (API), we supply OEM-quality replacement laser cutter parts at up to 70% off retail prices. Or, if you're looking to purchase a full machine, our affiliate company Alternative Machinery Sales can help you find the best fit for your facility.

Download our catalog to learn more about our products and services, and feel free to contact our team with any questions.