How to Achieve Laser Cutting Accuracy

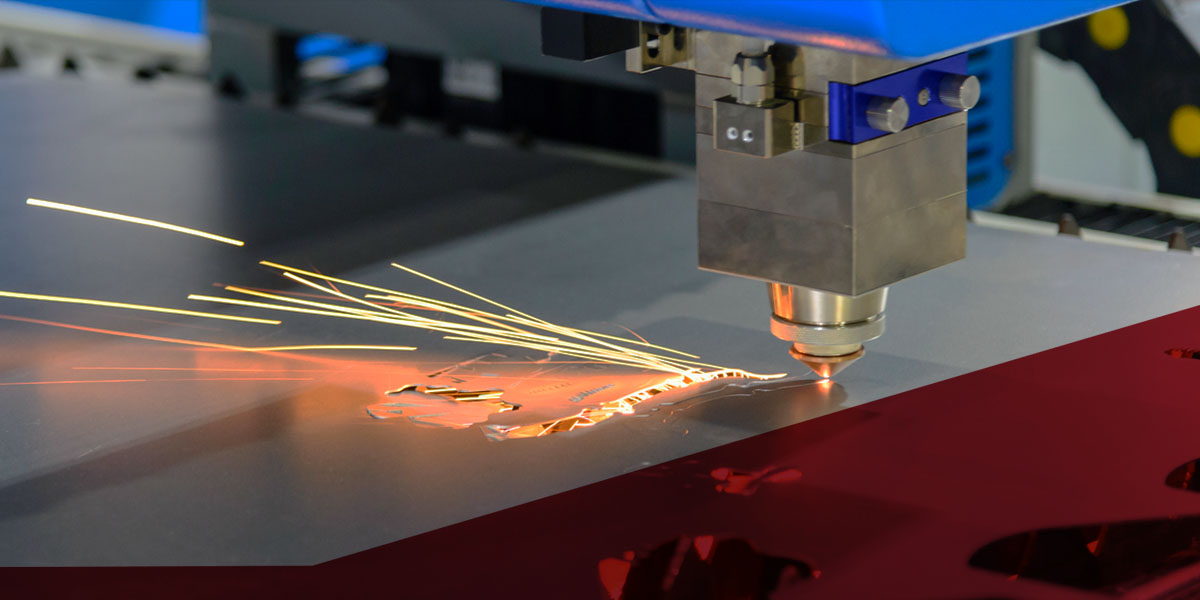

Laser cutting accuracy isn’t just a technical term. It’s one of the most essential components of the laser cutting machine industry. As an owner or operator in the industry, understanding the level of precision this equipment can offer allows you to know the capabilities of your machines, set appropriate quality standards and ensure you deliver quality products with accuracy and reliability.

How can I improve the precision of my laser cutting operations? What factors will influence the accuracy? How do the different types of laser cutters compare? We know how vital cutting accuracy is to your operation, so we’ve created this detailed guide to help you get all the answers you need.

How Accurate Is Laser Cutting?

Laser cutting is known for its excellent accuracy and precision. This makes it a top choice for industries that require high-quality cutting services. However, the precision achieved in laser cutting is influenced by various factors, such as the type of machine you’re using, the characteristics of the material being cut and the cutting parameters you’ve configured for the task.

When we consider the accuracy of laser cutting, we also need to recognize its significant advantages over traditional cutting methods like water jet cutting — which uses a high-pressure stream of water — or mechanical cutting — which uses a spinning blade. Laser cutting stands out for its ability to deliver precision and consistently execute intricate cuts.

What Affects Laser Cutting Accuracy?

Laser cutting tolerances play a significant role in cutting accuracy. These are basically the "rules" that define the acceptable variation in dimensions for laser cut parts. For example, laser cutting tolerances for steel often depend on the thickness of the material. >

Other factors can influence how accurately a laser cutting machine operates. These include:

- Machine calibration and maintenance: This helps to maintain cutting precision by ensuring the machine is aligned correctly and in optimal working condition.

- >Cutting speed and power settings: Finding the right balance between cutting speed and power settings can help your team achieve precise cuts, as variations can impact the cuts' accuracy.

- Material properties: Different materials with unique thicknesses and composition respond differently to laser cuts.

- Beam quality: The quality of the laser beam and focusing optics determines how accurately a machine can cut through materials.

- Environmental conditions: Unstable temperatures, air quality and humidity can impact how effectively the laser machine works.

- Material handling: Proper material handling is essential for maintaining alignment and stability while cutting, which can influence the cutting accuracy. Using shields developed for laser debris can also prevent unwanted dirt and other small objects from damaging your equipment.

- Software and programming: The cutting path programmed into the machine's software directly influences the accuracy of the final cut, so the software and programming you use are essential.

What Types of Laser Cutters Are Most Accurate?

Different types of laser cutters offer various technologies, designs and capabilities. Understanding the characteristics of each of these cutters can help you decide which machine will best suit your needs. Below, we explore some of the most popular options in the industry.

1. Fiber Laser Cutters

Fiber laser cutters use fiber optics to help them generate a concentrated laser beam that can achieve high-quality cuts. They’re known for their precision, high cutting speeds and efficiency in cutting through metal materials.

- Advantages: Great at cutting thin to thick materials. They cut at high speeds and low costs.

- Applications: Fiber laser cutters are also ideal for cutting steel, aluminum, copper, and other metals with precision. This makes them great for the automotive, aerospace, and any other industry that requires precise metal cutting.

2. CO2 Laser Cutters

As the name suggests, these machines use a carbon dioxide mixture to produce a laser beam. Operators then focus this beam using mirrors and lenses. Carbon dioxide (CO2) laser cutters are effective in cutting non-metal materials with high accuracy.

- Advantages: The ability to cut through various materials, including wood, plastic, fabric and acrylic, with precision. They’re also suitable for intricate designs and detailed patterns.

- Applications: CO2 laser cutters work well in industries where intricate designs and patterns are needed, such as the textile industry or graphic design.

3. Crystal Laser Cutters

>Crystal laser cutters generate the laser beam using crystal materials. These crystals help with accurate cutting because they produce high-intensity beams.

- Advantages: Their most significant advantage is the ability to handle a variety of materials, including ceramics, some plastics and metals.

- Applications: Crystal laser cutters are often used for medical devices, electronics and any industry that requires high precision.

How to Improve Laser Cutter Accuracy

Above, we highlighted a few key factors that affect laser cutting precision. Now, we’d like to focus on a few steps you can take to improve the accuracy of laser cutting in your operation.

1. Regular Maintenance and Calibration

Maintenance and calibration involve scheduling checks and procedures to ensure your machine works at peak performance. These include routine inspections to align the laser beam path, verifying motion accuracy and ensuring cleanliness of all optical components. These small yet significant tasks can help you optimize the performance of your laser cutting machine and ensure consistent accuracy and quality.

2. Material Selection and Preparation

A key component of laser cutting precision is choosing the right material for the type of machine you’re using. You’ll need to consider:

- Material thickness: Thicker materials often require different cutting settings than thinner materials.

- Material quality: Opting for high-quality materials with consistent properties can help you ensure uniformity in the cutting process and results

- Material compatibility: It is essential to choose materials suitable for laser cutting and the type of laser cutter you’ll be using.

- Material composition: Consider the composition of your material, including any coatings or surface treatments that may affect the cutting process.

In addition, it’s essential to prepare your material properly for the cutting process. This includes ensuring that the material is clean and free from contaminants, maintaining flatness and stability throughout the cutting process, and handling your material carefully to avoid scratches, dents or other imperfections.

3. Regular Quality Checks

Implementing a quality control process can help you address challenges before they occur. These checks involve regularly servicing and inspecting cut parts, dimensions and surface quality to ensure that each piece meets your desired results.

4. Implementing Advanced Software Solutions

The right software solutions can help you improve your cutting and increase accuracy. Advanced software with features like auto-focus and real-time monitoring can enhance accuracy and efficiency. For example, you can incorporate software tools that automatically adjust cutting parameters based on material properties and optimize cutting paths to help improve accuracy.

Achieve Laser Cutting Accuracy With Alternative Parts, Inc.

Prioritizing accuracy isn’t just a technical consideration — it requires strategic thinking to help you drive success for all your operations.

At Alternative Parts, Inc. (API), we offer our customers competitive prices for quality parts. We also provide quality maintenance and repair services for your laser cutting machinery. You can search API's extensive list of industry-leading brands for all your needs.

Contact our team today to learn more about how you can achieve accurate laser cutting and improve operational efficiency.