Industrial laser cutters provide speed, accuracy and value to manufacturing companies across various sectors, including aerospace, apparel, packaging and much more. Understanding the key differences between a carbon dioxide (CO2) laser and a fiber laser is essential for choosing the right equipment for your facility.

This article will explain each type while weighing out the pros and cons of CO2 and fiber laser cutting machines.

1. What Are the Basic Operating Principles?

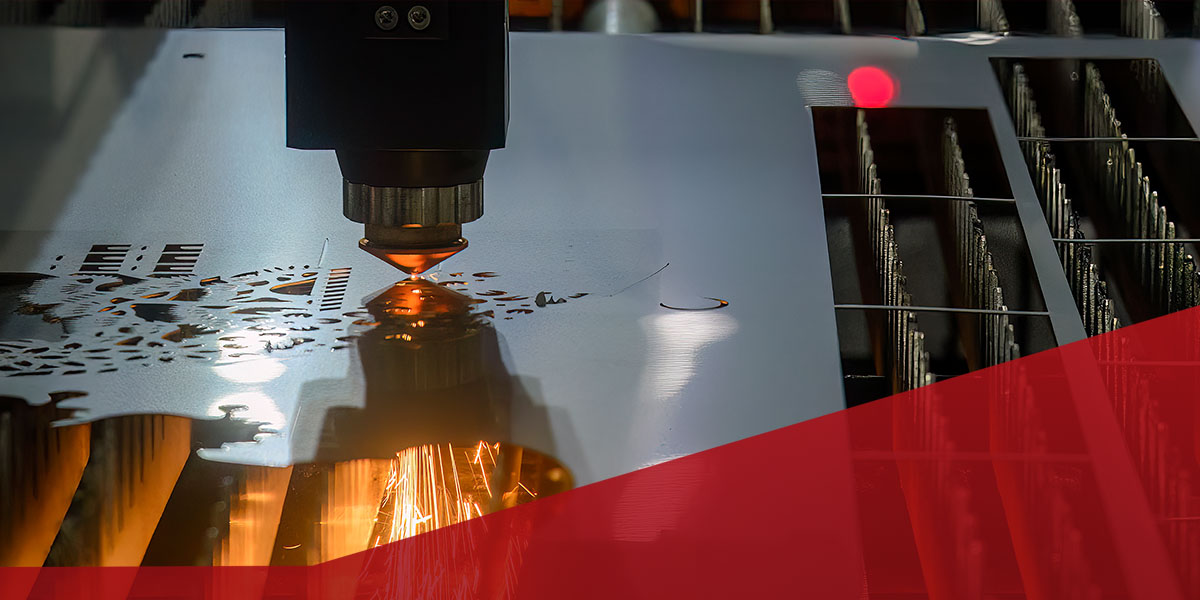

A CO2 laser works by sending electricity through a tube filled with gases including CO2, nitrogen (N) and helium (He), which creates a beam of light. That beam then reflects off a mirror to generate additional heat before hitting the item to be cut.

The typical CO2 laser wavelength is approximately 10.6 micrometers or 10,600 nanometers. Other wavelengths are also available if needed, though they are less common.

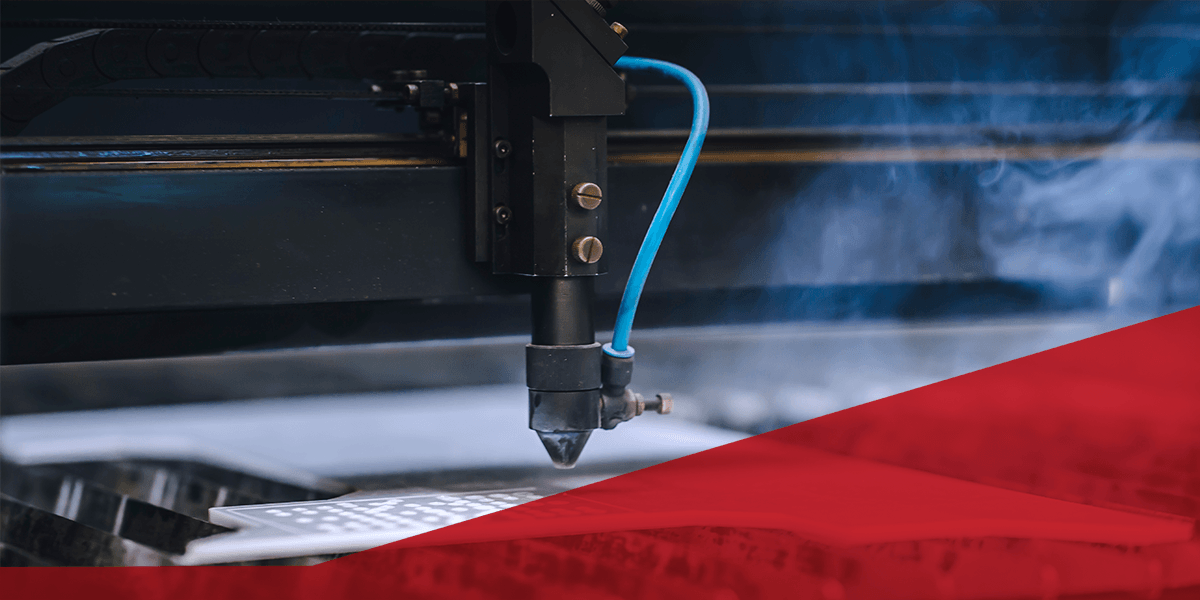

A fiber laser is similar in its technique for creating a light beam, though it directs the beam through a fiber optic cable instead of a set of mirrors. This cable is often covered with rare conductive elements, such as ytterbium and thulium, which help to produce an intense infrared beam.

Fiber laser cutters usually operate at a wavelength of 1.06 micrometers or 1,060 nanometers, which falls in the infrared range. Because this frequency is much higher than that of CO2 materials, the beam behaves differently and has greater cutting capability.

2. Which Materials Are Compatible With Each Laser?

Because they operate in different ways, CO2 laser cutters and fiber laser cutters work best with different materials. A CO2 laser can create fast, precise cuts in most non-metallic materials:

- Textiles

- Wood

- Acrylic

- Plastic

- Cork

- Leather

- Rubber

- Paper

- Marble

- Granite

- Tile

- Ceramics

You can also use a CO2 laser cutter to cut through thinner pieces of metal, though your results will be less accurate due to the metal's reflective qualities.

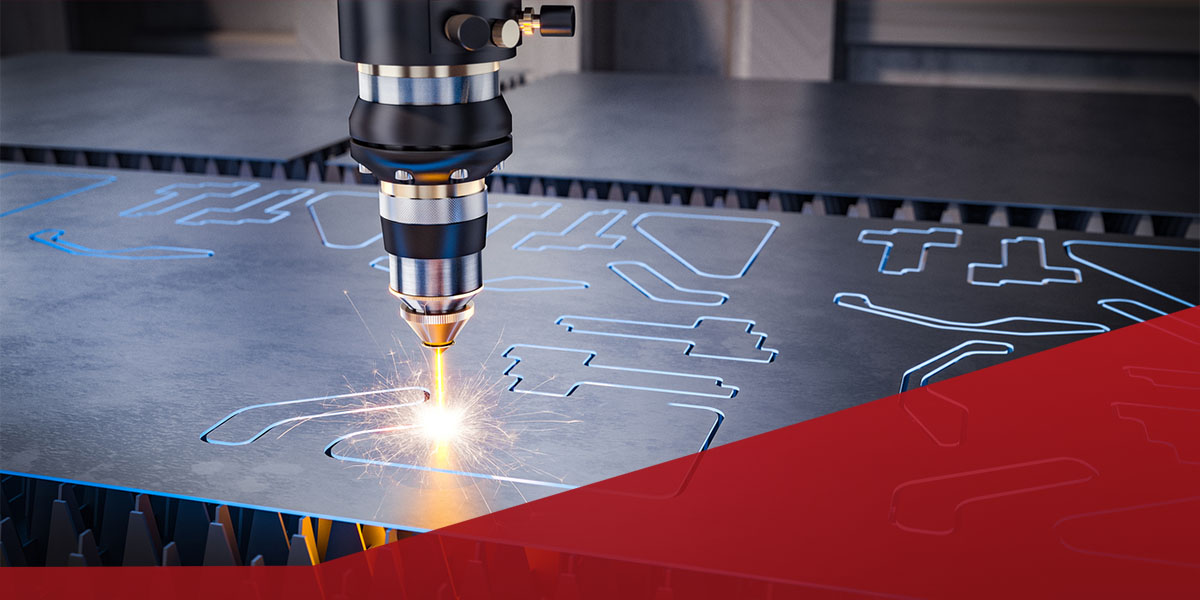

Fiber laser cutters, on the other hand, are designed exclusively for cutting and marking metals in industrial settings. Their smaller focal points create a more concentrated beam, providing more power to penetrate metal surfaces such as:

- Steel

- Aluminum

- Brass

- Copper

- Silver

- Gold

- Titanium

3. Which Laser Is More Versatile?

Generally speaking, a CO2 laser cutter is more versatile because it can handle more diverse applications than a fiber cutter. Some examples include:

- Textiles: CO2 laser cutters can quickly and accurately cut through even the most delicate fabrics, which enables them to create elaborate patterns on clothing and home goods without causing fraying or other imperfections.

- Packaging: A CO2 laser cutter can be useful for various applications in packaging, such as creating barcodes, serial numbers and expiration dates.

Fiber laser cutters, on the other hand, are the best industrial laser cutters for highly regulated industries requiring precise metal pieces such as:

- Automotive: Fiber laser cutters can quickly and accurately cut automotive parts such as body panels, engine components, exhaust pipes and more.

- Aerospace: Manufacturers of aircraft and satellites can rely on fiber laser cutters to create parts for various types of equipment, including airframe structures and engine components.

- Firearms: The precision and speed fiber laser cutters provide are advantageous for several different applications in the U.S. firearms industry, including serial number marking, firearm customization and more. Note that each specific application in this industry requires a different type of federal firearms license (FFL).

4. What Cutting Speeds and Quality Can You Expect?

Both types of laser cutters produce high-quality results when used with compatible materials. For example, a fiber cutter will deliver better results on a reflective surface than a CO2 cutter — and a CO2 laser cutter will deliver cleaner, more precise cuts on textiles and organic surfaces.

As long as you follow that rule, the main difference lies in their overall operating speed and efficiency. CO2 laser cutters can take up to half an hour to warm up, whereas fiber laser cutters are ready for operation instantly upon startup because they lack internal moving parts. Fiber cutters also cut several times faster than CO2 lasers, which is why they are best suited for use with metals.

That said, the ideal cutting speed for each system will be well below its maximum speed. Consistently running at top speed burns through consumables and fuel, which drives up your maintenance and operating costs.

5. What Are the Typical Operating Costs and Maintenance Requirements?

Typically, a CO2 laser cutter requires a lower upfront investment and higher maintenance costs due to their complex internal construction. Parts that need the most attention include:

- Mirrors

- Gas refills

- Bellows

- Oscillators

Properly maintaining these parts can take several hours each week, which can lead to significant losses in productivity.

Fiber laser cutters are the opposite — while you'll usually have to pay more upfront, maintenance and operating costs are significantly lower than CO2 laser cutters. The optics cable is coated, which means it is protected from environmental factors like dirt, moisture and temperature changes.

Because you only need to spend a few minutes on fiber laser maintenance each day, you can maximize productivity and minimize costs.

Example: How Maintenance and Repair Costs Differ

Misalignment is a common issue between both types of laser cutters. It occurs when the cutting head collides with a tipped part, knocking the lens out of alignment and causing a noticeable performance decrease.

While both types can experience misalignment, it's a more serious issue for CO2 lasers because they contain more mirrors. While correcting a misaligned fiber laser only requires you to adjust one lens, you have to adjust multiple in a CO2 laser cutter. Maintenance and repair tasks tend to be both more costly and time-consuming for CO2 cutters as a result.

6. What Are the Training and Safety Requirements?

Regardless of laser type, all operators should have a basic laser cutting operator certification. More specific training requirements will depend on the class of laser you're using. The higher a laser's class, the more risk a laser poses to operator safety — operating any laser in class 3b or 4 requires you to hold an on-site laser safety officer (LSO) certification.

That said, most laser cutters fall under class 1 according to the American National Standard Institute (ANSI) Z136.1 standard. The laser beams are covered by a physical barrier, which protects operators' eyes and skin from serious damage. Employees operating class 1 lasers can do so with minimal protective gear or cautionary practices.

Alternative Parts, Inc Can Help You Save on Laser Cutting Equipment

Whether your facility uses a CO2 or a fiber laser cutter, preventive maintenance and regular part replacements are essential for keeping costs low and maximizing productivity.

That's where we at Alternative Parts, Inc (API) come in. API manufactures and distributes high-quality replacement parts for metal fabrication equipment like laser cutters, laser welding systems and more. With discounts of up to 70% on pieces that meet or exceed OEM specifications, you can count on us to provide affordable parts without sacrificing quality.

Are you looking to purchase a specific type of laser cutting machine? View all new and used machinery for sale through our affiliate, Alternative Machinery Sales.

Request our latest catalog to learn more about any of our laser products and services, and feel free to contact our team with any questions you have.